Industrial Coffee Grinder Overview: Boost Performance and Quality

In the affordable landscape of coffee production, selecting the appropriate industrial coffee grinder plays a critical role in enhancing both effectiveness and product top quality. Comprehending the subtleties of various grinder types and crucial attributes-- such as adjustable work settings and durable building-- can significantly influence the last flavor profile of the coffee. Moreover, the optimization of the grinding process, combined with attentive maintenance, is crucial for sustaining performance gradually. As we explore these vital components, it comes to be apparent that the effects extend beyond simple devices choice, impacting overall company success in manner ins which call for closer exam.

Recognizing Grinder Types

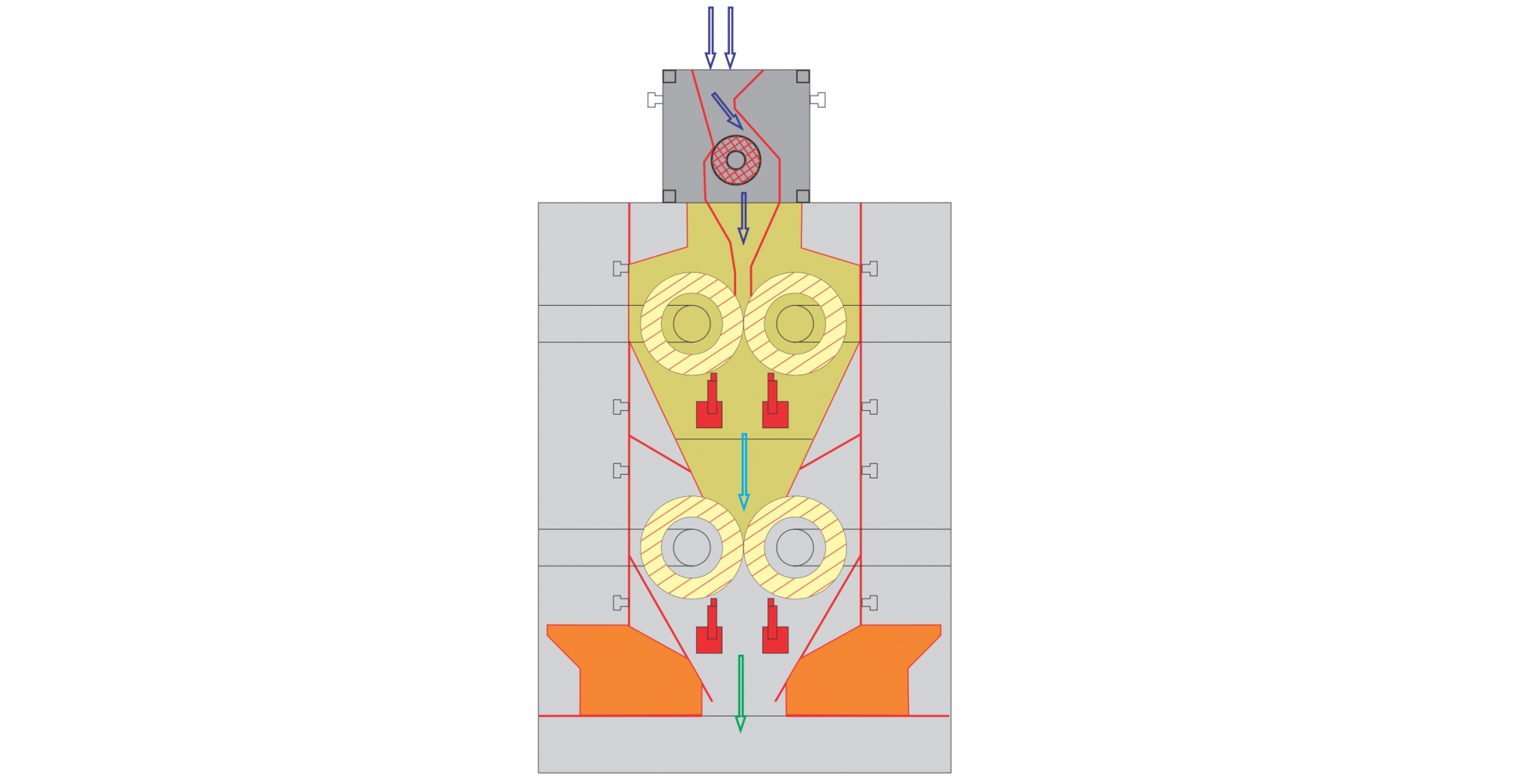

When selecting an industrial coffee mill, comprehending the numerous kinds readily available is crucial for maximizing both flavor extraction and operational efficiency. The two key sorts of grinders are blade mills and burr mills. Blade grinders make use of sharp blades that slice coffee beans into irregular sizes, causing unequal extraction and potentially unwanted tastes. While blade grinders are commonly a lot more economical and suitable for small-scale procedures, they are normally not recommended for commercial usage.

Ultimately, choosing the appropriate kind of mill is important to maintaining high quality and efficiency in coffee manufacturing, making it essential for services to invest in top notch burr mills for optimal outcomes.

Key Functions to Take Into Consideration

Selecting a commercial coffee grinder calls for mindful consideration of a number of key attributes that can significantly influence both efficiency and the total coffee experience. One of the key facets to assess is the grinding system. Burr mills are typically preferred over blade grinders, as they supply a regular work dimension, which is vital for optimal extraction and taste.

Another vital attribute is the grinder's ability. A functional mill with numerous settings allows you to tailor the work dimension to various brewing methods, enhancing the coffee's taste account.

The construction product also plays a function in toughness and upkeep. Stainless steel components usually offer longevity and are less complicated to cleanse, which is necessary for preserving hygiene standards. Review the mill's noise degree, especially in an active coffee shop or production setting, where excessive noise can be turbulent. Investing in a mill that balances these functions can considerably enhance both functional effectiveness and the top quality of the coffee served.

Optimizing Grinding Refine

To achieve the finest outcomes in coffee prep work, enhancing the grinding process is essential. The grind size substantially influences extraction, flavor, and general high quality of the brewed coffee.

Additionally, keeping track of the grinding rate can maximize the process. Slower grinding commonly generates much less warmth, preserving delicate tastes and aromas. On the other hand, much faster grinding might produce extreme warm, adversely influencing the coffee's top quality.

Upkeep and Treatment Tips

Appropriate maintenance and treatment of industrial coffee mills are essential for ensuring optimum efficiency and long life. Normal cleansing is the foundation of maintenance; residue buildup can impact flavor and grinding efficiency. It is advisable to cleanse the mill after each usage, cleaning down the exterior and removing any kind of coffee premises from the burrs.

Furthermore, check the grinding burrs for deterioration. Boring burrs can compromise work consistency, so they should be changed as essential. Industrial Coffee Grinder. Occasionally adjusting the grinder is likewise you could try these out important, as this more maintains the wanted work size for various brewing approaches

Lubrication of relocating parts need to be done according to the manufacturer's specifications, as this minimizes friction and lengthens the life of the devices. It is important to make use of food-grade lubricating substances to make sure safety and conformity with health laws.

Last but not least, keep the mill in a steady and completely dry setting to avoid rust and rust. By sticking to these maintenance and treatment ideas, operators can improve the performance of their industrial coffee mills while making certain premium outcome and prolonged functional life.

Return on Financial Investment Evaluation

Assessing the return on financial investment (ROI) for commercial coffee mills is crucial for services looking for to maximize their coffee production capabilities. A thorough ROI analysis aids determine the financial practicality of spending in high-grade mills, permitting organizations to weigh the initial costs against prospective gains.

To perform a comprehensive ROI analysis, businesses should consider numerous vital factors. Evaluate the purchase price of the grinder, consisting of installation and any needed adjustments to existing facilities. Next, compute functional expenses, consisting of energy consumption, maintenance expenditures, and labor performance renovations. High-performance mills frequently lead to lowered grinding time and raised throughput, which can substantially boost performance.

Furthermore, consider the influence on item top quality. Industrial Coffee Grinder. Superior this grinders generate a more regular grind dimension, which can boost flavor accounts and client complete satisfaction, ultimately driving sales. By boosting the quality of the final product, businesses can warrant higher prices, resulting in increased profits

Conclusion

In recap, an industrial coffee grinder plays a pivotal duty in enhancing both performance and product high quality within coffee manufacturing. By choosing top quality burr mills equipped with necessary features such as adjustable work settings and long lasting construction, services can ensure ideal taste removal. Additionally, routine upkeep is essential for sustaining mill performance and maximizing client fulfillment. Eventually, the critical financial investment in a dependable grinder contributes substantially to boosted revenue and competitiveness in the coffee industry.

In the competitive landscape of coffee production, picking the appropriate industrial coffee grinder plays a critical duty in enhancing both efficiency and product high quality. The two primary types of mills are blade grinders and burr grinders. Within the burr mill group, there are level burr grinders and conical burr grinders, each with its benefits. Burr grinders are typically chosen over blade grinders, as they supply a constant grind dimension, which is vital for ideal extraction and flavor.

In summary, a commercial coffee grinder plays a critical role in boosting both effectiveness and product quality within coffee manufacturing.